Recently, I had the opportunity to test the internal electronics of several popular Router UPS devices. Honestly, most of them are useless products and will make the router sick within days. Oh, that’s another story, and I’ll post an in-depth article about them (how and why) later.

I still believe you can build a reliable Wi-Fi router/CCTV camera UPS with a 12V/7Ah SLA battery. You may be wondering why I still cling to that old battery technology in this lithium+ battery age, but I have some reasons for that. So, let’s get started.

SLA/VRLA/SMF/AGM…?

SLA and VRLA are different acronyms for the same battery, Sealed Lead Acid or Valve Regulated Lead Acid. The SLA/VRLA batteries, also knowns as SMF (Sealed  Maintenance Free) batteries, do not require constant maintenance and normally do not emit any fumes or gases on a continuous basis. These batteries are completely sealed, thus eliminating the risk of acid spillage during transportation, and due to their construction, we can also mount them in any orientation.

Maintenance Free) batteries, do not require constant maintenance and normally do not emit any fumes or gases on a continuous basis. These batteries are completely sealed, thus eliminating the risk of acid spillage during transportation, and due to their construction, we can also mount them in any orientation.

AGM (Absorbed Glass Mat) refers to a specific type of SLA/VRLA where the electrolyte is absorbed into separators between the plates consisting of sponge-like fine glass fiber mats. AGM batteries are extremely resistant to vibration, are totally sealed, non-spillable, and maintenance-free. AGM offers better cycling performance, minimal gassing, and acid leakage when compared with conventional lead-acid batteries.

AGM batteries are also the preferred solution for start-stop vehicle technology. The start-stop vehicle technology automatically shuts off the engine when the vehicle stops, such as at a traffic light or in stop-and-go traffic, and restarts it quickly and quietly when the clutch is engaged or the brake pedal is released (https://www.autobatteries.com)!

Cycle/Standby/Float Use…?

When learning about SLA battery charging and discharging rules, you may find many complex terms such as standby use and cycle use. Let me describe it briefly here.

Unfortunately, many YouTube videos about making SLA battery chargers do not explain those critical terms. The real intention of some YouTubers is not to share valuable knowledge, but to duplicate other people’s ideas and shoot videos without knowing anything technically – only for monetary gains, and/or to support their PCB sponsors!

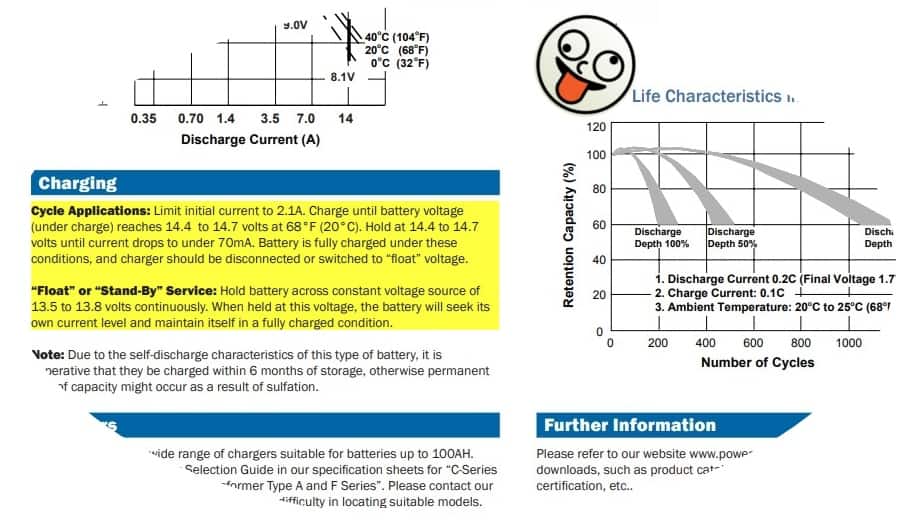

First off note that SLA batteries may be charged through different charging techniques, to obtain maximum battery service life and capacity, along with acceptable recharge time and economy, constant voltage-current limited charging is the best method. This charging method can be used for both cyclic and standby/float applications.

The constant voltage charge method applies a constant voltage to the battery and limits the initial charge current. Here, a DC voltage between 2.3V per cell (standby/float) and 2.45V per cell (fast) is applied to the terminals of the battery. Depending on the state of charge (SoC), the cell may temporarily be lower after discharge than the applied voltage. After some time, however, it should level off.

A Cyclic application is one where a battery is discharged and charged on a regular schedule. A typical application would be an electrical power load shedding system. A standby/float application is one where a battery is maintained, using a float charge voltage, in a full charge state ready to support an attached load immediately should the mains supply fail. A typical application would be an uninterruptable power supply (https://www.yuasa.co.uk/).

In short, Cycle use is when the battery is used to power devices every day, which discharges the battery, and Standby/Float use is when for the majority of the time the battery remains 100% charged in standby.

Cyclic/Cycling applications usually require recharging to be done in a relatively short time. The initial charge current, however, must not exceed 0.30 x C amperes. On the other hand, Standby applications generally do not require that the battery be charged as fast or as frequently as in cycle operation. However, the battery must be kept constantly charged to replace the energy that is dropped due to internal loss and declension of the battery itself (https://www.power-sonic.com).

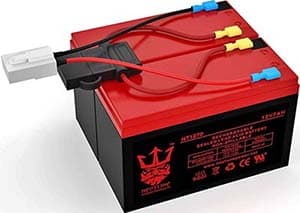

See, these are clearly printed on the NT1270 12V/7Ah battery shell above.

- Standby Use: 13.6 to 13.8V

- Cycle Use: 14.5 to 14.9V

- Initial Current: 2.4A maximum

(Nominal Temperature Range: 25°C ± 3°C)

However, you should pay close attention to the requirements of your specific SLA battery before choosing a charger. Datasheets/spec sheets can be of great help here because the actual demands may vary slightly depending on the model.

Example https://autosolar.es/pdf/VISION-12V-7AH.pdf

Just a quick note, readers often ask me about the ideal charging current for recharging SLA batteries. My answer is 25% of the Ah capacity (the voltage of charging is also important).

So, the charging current of a 12V/7Ah SLA battery should be no more than 1.75A to prevent thermal runaway and battery expiration. Importantly, if you have other device connected to the battery during charging, it also needs to be powered, so you need to add that to your calculations. In this example, if your battery is wired to a load of 1A, the charging current needs to be 2.75A (https://www.upsbatterycenter.com/). Keep the questions coming

Crude 12V/7Ah SLA Battery Charger – Ideas for Design!

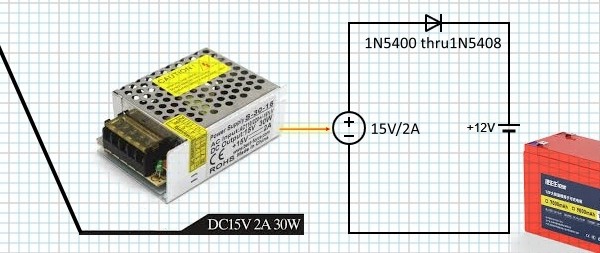

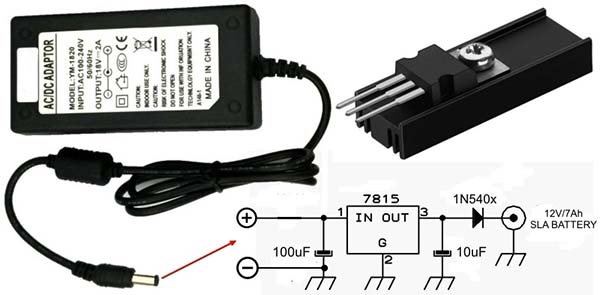

The first idea is to charge a 12V/7Ah SLA battery from a 15VDC/2A power supply. It works, it is uncritical to build and uses only easy-to-find parts, so it has something in its favor. The crude charger consists of two stages – the first is a 15V/2A SMPS, and the second is a standard recovery rectifier 1N540x, which prevents reverse current and also lowers the charging voltage a bit (1V maximum).

The resulting output voltage is fine for charging a 12V/7Ah SLA battery to full charge but is too high as a trickle charger, so don’t leave this charger setup permanently connected to the battery. If you would like to do, then add a 0-15VDC analog voltmeter across the battery terminals to indicate the battery voltage level in a simplistic way.

Needless to say, this rude idea can also be implemented using an 18V/2A laptop charger (AC/DC Adaptor) as shown in the below schematic. Here, the second stage is a 15V fixed voltage regulator IC – L7815 – bolted to a bit heavy TO-220 heatsink. Not very tidy, but it works!

Multi-Stage SLA Battery Charge Profile!

Charging SLA batteries does not seem a particularly hard process. Simple SLA battery chargers will do the job for a while, but the battery lifespan will be greatly reduced by using crude SLA battery chargers like this.

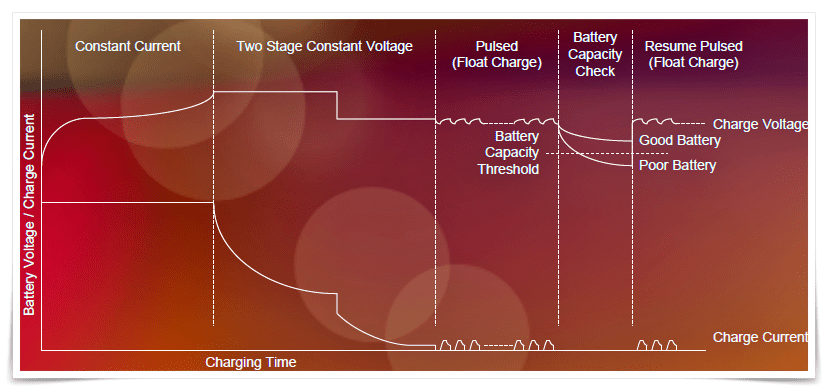

Now note that using a combination of constant current (CC) charging and two-stage constant voltage (CV) charging techniques (and also by monitoring the battery terminal voltage and temperature), a multi-stage charge profile can be implemented to reduce stress on the battery while giving the shortest possible charge time.

The first stage of the multi-stage charge process is the constant current mode where the charging current should limit to a quarter of the battery capacity which is 1.75A for a 7Ah battery. This process continues until the terminal voltage reaches 14.4V (2.40V/cell).

Thereafter, the charging process moves to the second stage where the output changes from constant current to constant voltage. When the charge current drops to 0.05C Amperes, which is 0.35A for a 7Ah battery, the battery will have recovered approximately 70-80% of its charge. At this point, the output voltage reduces to 13.65V (2.275V/cell).

The remaining 20-30% of the charge is carried out at this lower voltage in order to prevent over-charge. The charge process will stay in this mode until the battery is fully charged.

The final part of the multi-stage charge process is the float charge cycle which provides an intermittent float charge as shown in the below figure (www.silvertel.com).

Going Further …

I already rigged up an improved SLA battery charger to charge my 12V/7Ah SLA battery with an 18V laptop AC/DC adaptor. The charger circuitry, however, only implements the constant current stage of the standard lead-acid battery charge curve, since that is when most of a battery’s capacity is refilled and is much simpler to build than one with a pretty complex multi-stage controller logic.

If I did use a tiny microcontroller, implementing all stages of the charge cycle would be much easier, but I opted not to include that so far (I’ll probably play with that at some point). The complete project details will be posted here after some time. The next one in the queue is the construction project of an economic Wi-Fi Router/CCTV UPS device. So, stay tuned!

Very nice write-up. I was thinking the same thing about most YouTubers but had not put it into words.

Jeff: Thank you! I am grateful for your feedback and support.🤍

This answered a lot of questions, but I have one more. How could you figure the largest battery you could hook up to a battery backup and have it charge fully? In my case I have a couple APC ES 650’s kicking around. The come with a 7Ah battery, but I’ve seen 9Ah batteries in the same package. The charging output is 5w and the charging voltage is 13.5v (.370A).

Rich D: Quick answer – hope this helps https://www.atbatt.com/chargers/sla-battery-charger/buyers-guide/ Thanks!

When is the battery ‘done’ charging? I would assume current should drop below some percentage of C, but I don’t know what that might be.

Daniel P: In principle, an SLA battery is fully charged when the current it accepts drops to less than 1% of its rated capacity at a charge voltage of 2.45 ± 0.05V per cell. At this point, you can disconnect the charger or switch it to a float voltage of 2.25 to 2.30V per cell.

See also https://www.power-sonic.com/blog/how-to-charge-a-lead-acid-battery/

Thanks!

Very good article, thank you, it is very interesting.

Nate: Glad to hear, Thanks!