Building track lights and spotlights seems to be an obsession of mine. I built my first one in my school days or so, and this time my project thought is on simple power LED light heads with several interesting applications.

AC230V LED Spotlight

At first, note that the final do it yourself project is picky regarding the exact flavor of light head you use, as I’m going to share a number of LED light head ideas here in this post. Well, let’s start with a pretty cheap yet elegant LED spotlight made up by Philips. Surely some of my readers would ask why I didn’t start with the construction note of a do it yourself LED track light or spotlight. The reason is simple. Although there isn’t very much to improve in the electronics of a tight commercial design, we can learn something salutary by doing an in-depth analysis. Okay, get ready to pry the lid off!

The “Philips 2W Round Astra Spotlight” available in different colors (red, green, blue, yellow, white) comes with its own LED driver/ballast. So you can use it out of the box instantly as a AC240V spotlight or ceiling light, or as a track light but only after some alterations. Maximum output current of the driver is 150mA at 6.5VDC, and the maximum output power is 1W. Maximum input power is 2W.

DC 3.7V/5V Build

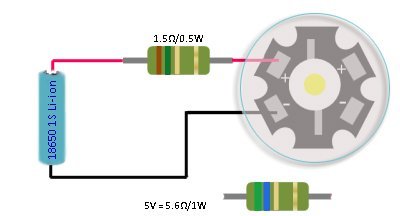

That’s okay. But if you’re trying to build a battery-powered version, you can omit the bulky LED driver box. If so, just try a single series resistor (ballast resistor) to power one 1W star white LED from a 18650 1S Li-ion or LiPo battery. A devoted constant current LED driver circuitry is not very essential for the simpleton application. Moreover, you can run it from a USB power supply as well by changing the value of the series resistor (see below).

LEDs with Reflectors

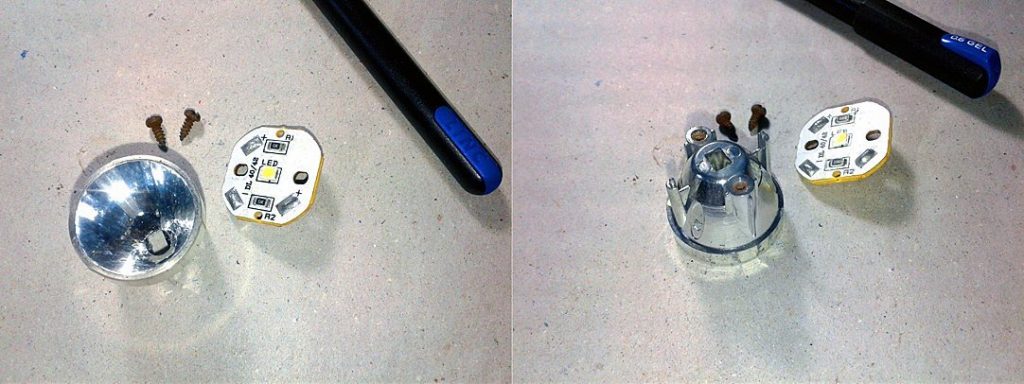

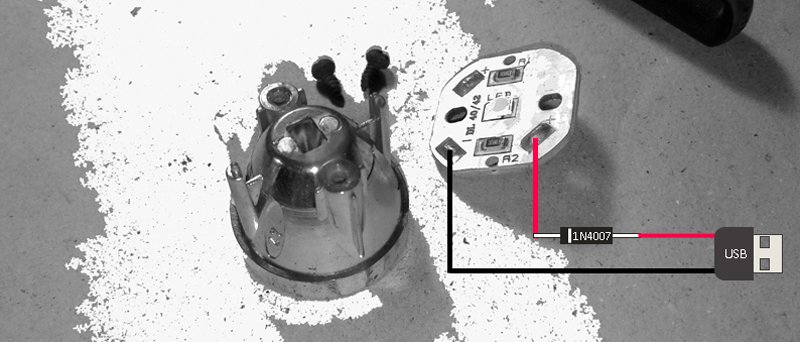

Like everyone else, I’m pretty sure you have, somewhere over the web, found small white LEDs with reflectors. Actually they’re built for battery-powered flashlight/dome light applications.

You can grab a box of suitable size for cheap and use them to make your own LED spotlights or track lights. Even a lazy search for “Square/Rectangular Hole Reflector COB LED” will return you a myriad of details. What I got from the Chinese online store is an mixed bag of narrow beam LED light heads specified for 1S Li-ion (3.7V-4.2V) battery operation (see below). It’s observed that maximum current consumption of the light head in hand is roughly 330mA while powered from a fully-charged 1S Li-ion battery. The ballast resistor is a parallel combination of two pre-soldered 3.3Ω chip resistors.

Since I intended to run it from a standard USB wall wart, an additional general-purpose rectifier diode was included in my final setup as shown in the below wiring diagram. Nice trick, eh?

Powerful LED Spotlights/Track Lights

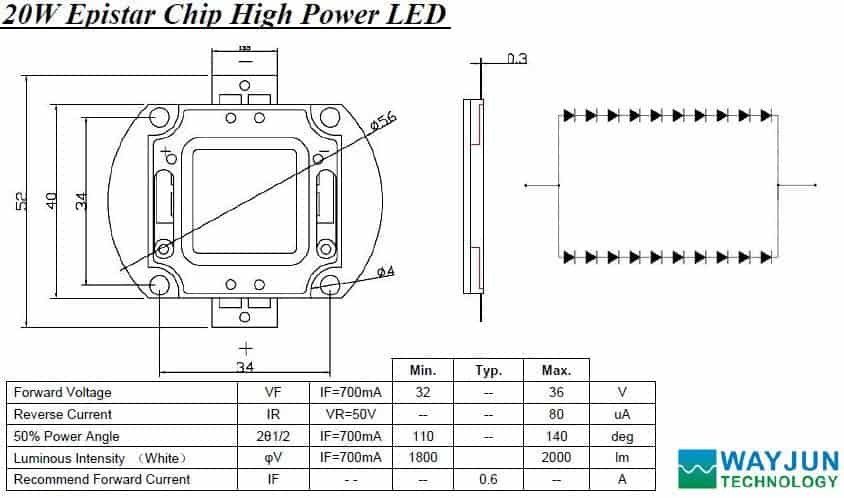

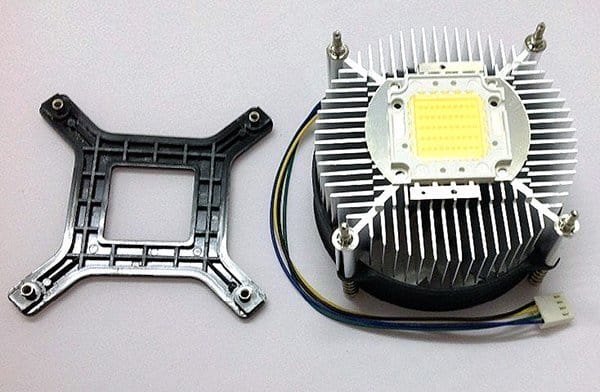

1W to 3W LEDs are enough for most spotlight and track light applications, mighty LED track lights with power up to 20W are commonly available though (see below). Now it’s worthy to note that track lighting is a method of lighting where light fixtures are attached anywhere on a continuous track device which contains electrical conductors. Track lighting is usually combined with directional lamps with reflectors, such as spotlights. These lamps can run under either AC mains voltage or a lower DC voltage.

You can go through this Wikipedia page to learn more about track lighting and track lights https://en.wikipedia.org/wiki/Track_lighting

Mighty DC LED Drivers

There are several proven methods out there for driving high-power LED’s, so I’ll go over a few in the following segments.

The ballast resistor (series-connected resistor) method is by far the most widely used method to drive power LED’s. Anyway, I do not recommend this simplest way for high power LEDs as it doesn’t work efficiently – there’re many tradeoffs!

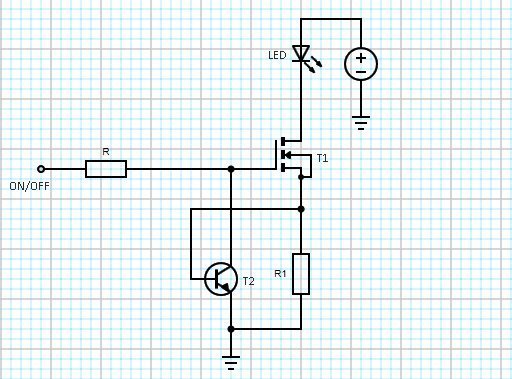

Let’s go to the next method. Following is the crude scheme of an ultra simple and quite common constant current source for driving power LEDs.

Here, the drive current flows through the LED, through T1, and through R1. When too much current flows through R1, T2 will start to turn on to turn off T1. Turning off T1 will decrease the current flow through the LED and R1. This way the setup ceaselessly monitors the LED current and keeps it exactly at the set point forever.

Just a sample calculation: For 650mA drive current, closest standard value for R1 is 1Ω (Vbe/If_LED = 0.7/0.65 = 1.07), and its rated power should be 1W. Note that the current set-point is somewhat sensitive to temperature. There are a lot of salient tutorials out there on the web already explicating this trick. A bit of Googling will help you find more elaborated themes.

Another Easy Climb

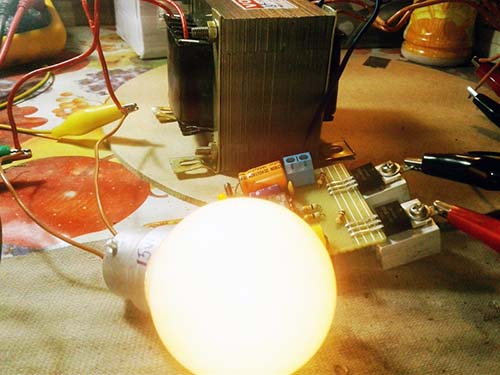

For a 20W power LED, the most sensible solution is the use of one off-the-shelf 20W power LED driver module designed specially for that particular application. I tried one of these pretty cool modules (there’re so many variants), bought from a Chinese electronics web store, and was quite happy with it.

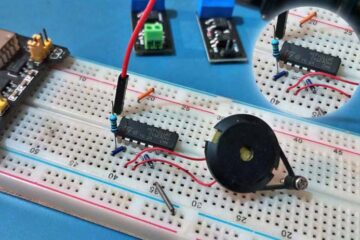

Key component of the module is XL6005, which is a 180KHz 60V 4A switching current boost LED constant current driver IC from XLSEMI (www.xlsemi.com). This fixed frequency PWM boost (step-up) LED constant current driver chip can drive a series 1W/3W/5W LED units with excellent line and load regulation. For the complete application information, refer its official datasheet http://www.xlsemi.com/datasheet/XL6005%20datasheet.pdf.

This the key data of a typical 20W high-power chip LED, usually sold by Amazon & eBay sellers:

A caveat against unfit practices: Note that a standard 20W LED mounted on aluminum metal-core printed circuit board (MCPCB), can be lighted directly, but I do not recommend operating it for more than five seconds without an appropriate heat dissipation mechanism. Therefore you must use a proper heatsink-fan assembly with your 20W LED!

Next in line…

Hope now you’ve got a couple of basic ideas for making elegant light heads for your own high-power LED based AC or DC spotlights and track lights. Now what? Nothing, but just follow one of the aforesaid ideas, and build a few at home!

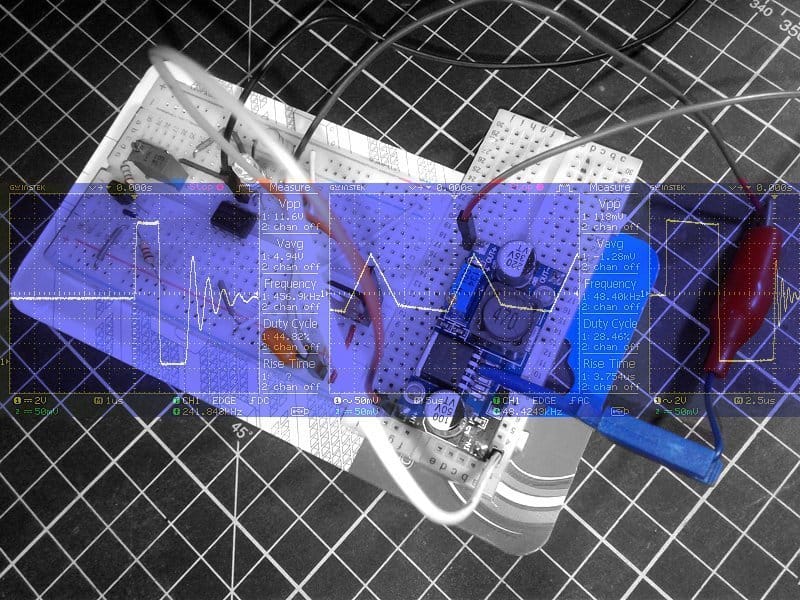

Perhaps you might not want to try customized Chinese LED drivers in your projects. Don’t worry, I’ll show you how to wire up your own constant-current power LED drivers by hacking very cheap and easy to use DC-DC switching regulator modules. Since the experiment is in progress, you may need to stay tuned for a while to see the do it yourself article here. I would certainly devote a little more time into making it better and nicer. Let’s see!

Postscript

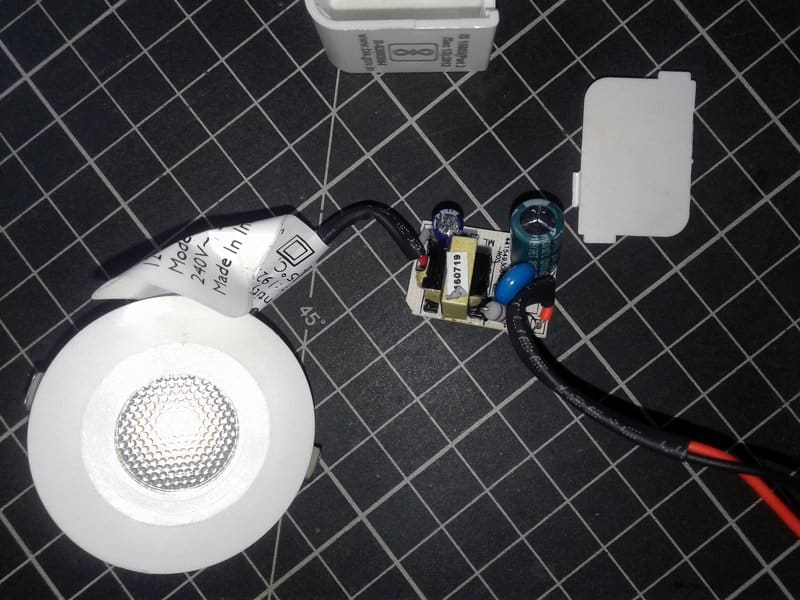

I mentioned before about the Philips Astra Spotlight. The way the light is built is similar to many Chinese cheapo spotlights. I’d wouldn’t be surprised if the Indian LED spotlight manufacturers use the same Chinese materials because of low cost due to volume. The image below shows the partial inside view of the spotlight. There’s a bit more to it than that, but it’s the gist of my next teardown & evaluation article. I’m certainly getting going to do a bit more research on LED spotlights, I think that will allow me (and you) to create better models.

I hope you find this article enjoyable and helpful. Let me know if you’ll be trying any in the comments below!